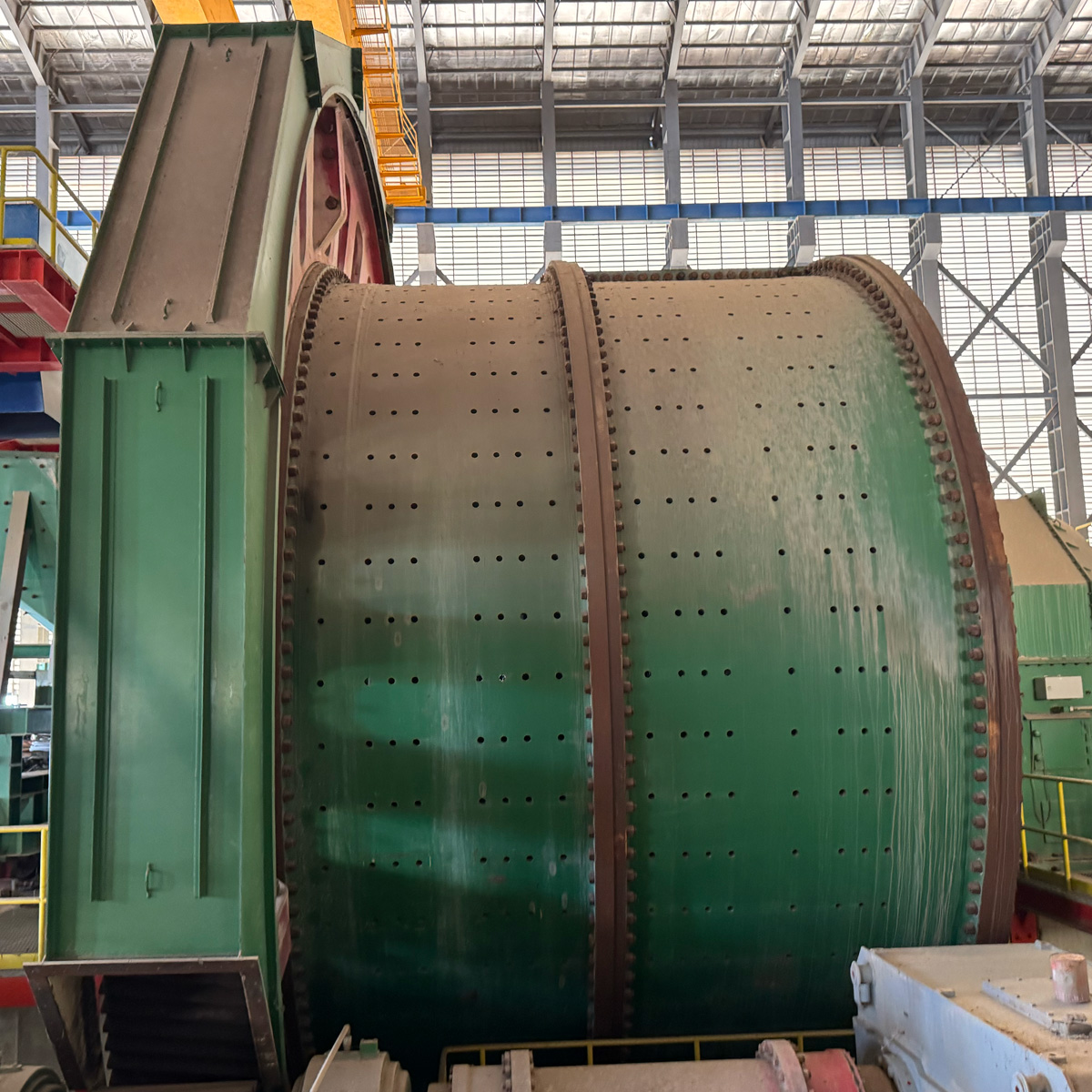

NHI 9.15 x 5M SAG Mill

A SAG mill (Semi-Autogenous Grinding mill) is a critical piece of equipment used in the mining industry to grind large chunks of ore into smaller, manageable pieces for further processing. Combining the principles of crushing and grinding, SAG mills utilize both grinding media, such as steel balls, and the ore itself to achieve size reduction. Typically used as the primary grinding stage in mining operations, SAG mills are large, high-capacity machines designed to process vast quantities of ore efficiently. They are particularly prevalent in the extraction of valuable metals like gold, copper, and platinum. While they offer high throughput and versatility, they require significant power to operate and are subject to wear and tear, necessitating regular maintenance.

A SAG mill (Semi-Autogenous Grinding mill) is a key piece of equipment used in the mining industry for grinding large chunks of ore into smaller, more manageable pieces. It is a type of grinding mill that uses a combination of grinding media (like steel balls) and the ore itself for the grinding process.

How it Works:

- Grinding Action: SAG mills rely on the tumbling action within the rotating drum. Large pieces of ore and grinding balls are placed inside the mill. As the drum rotates, the motion causes the ore to break apart.

- Semi-Autogenous: The “semi-autogenous” aspect means that while the mill uses some grinding media (steel balls), much of the grinding is done by the ore itself as it impacts and grinds against other ore particles.

- Size Reduction: The ore is reduced to a fine size, preparing it for further processing, such as flotation or leaching to extract valuable metals.

Key Features:

- Large Size: SAG mills are usually very large, with diameters reaching up to 42 feet.

- High Capacity: These mills can process large volumes of ore, making them ideal for large-scale mining operations.

- Variable Grinding Media: The amount and size of the grinding media can be adjusted to optimize performance based on ore characteristics.

Common Uses:

- Primary Grinding: SAG mills are typically used in the primary stage of grinding, reducing ore to a size suitable for downstream processing.

- Gold, Copper, and Platinum Mining: They are commonly used in mining operations that extract metals like gold, copper, and platinum.

Advantages:

- Efficiency: Combines crushing and grinding into one step, eliminating the need for additional crushing stages.

- Versatility: Can handle a wide variety of ore types and sizes.

- High Throughput: Suitable for processing large quantities of ore.

Challenges:

- High Energy Consumption: Requires significant power to operate.

- Wear and Tear: The grinding media and liners in the mill experience significant wear and must be replaced periodically.

Mine Liquidators is a global equipment marketplace. If you are in the market to purchase equipment reach out to us for what we have available. We have a large inventory of new/unused surplus and high quality used equipment around the globe. Please contact us for more photos and high quality video of this or any other piece of equipment you need.